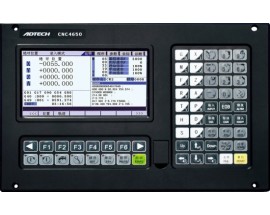

MCK300A 4 axis wood processing CNC controller--High cost-effective control system

Comprehensive functions,friendly interface,stable performance and easy to operate,it can greatly improve the efficiency of woodworking milling process,and reduce the operating requirements of the workers.

ADTECH Specifically for small and medium sized machine tool manufacturers both at domestic and abroad independent research and development of cost-effective numerical control system.

Adopt the ARM CPU and large scale programmable devices of high performance FPGA, real-time multitasking control and hardware interpolation technology, ensure um system under the precision machining of high efficiency.

256 m electronic trading to meet all kinds of large workpiece processing program.

7 inches color screen, interface can be made of parameter selection in both Chinese and English.

Features:

◆ After over half a century's development, woodworking machinery industry has established a complete system

from education, research, development, manufacturing, testing to sales in China. The industry has become one

of the important technical equipment industries in our country, playing an important role in the national

economy.

◆ Wood processing has become a stable process system, with the degree of specialization continuously

increasing. The rapid development of computer applications and CNC industry, have had an important role on

wood processing technology for innovation, wood processing industry system changes, as well as the

development of production processes and product design engineering, promoting woodworking machinery

from a purely mechanical products over to automation and intelligent products.

◆ CNC technology in the future will go more deeply into many other process areas of the wood processing.

Deficiencies and problems in the industry

In CNC process of today's woodworking machinery industry, CNC process of woodworking lathe and milling

machine is one of the most important content. CNC woodworking lathe and milling system currently used in the

vast majority of the industry is not developed specifically for the woodworking industry, so there are many

shortcomings and problems:

1. some using SCM, poor stability

2. System process is imperfect, not professional

3. Low processing efficiency

4. High cost for such control systems, and professional staff required for operation

Related Product Introduction:

MCK300A Wood Processing CNC Controller is developed based on Adtech powerful strength.

1.Adopt ARM9 processer and high performance FPGA motion chip, with excellent stability and

reliability

2.7inch LCD color screen, friendly display interface

3.Support woodworking lathe and milling technology, simple operation

4.Graphical display and processing real-time tracking function, can intuitively display graphic

shape in processing document

5.The system supports two-pole control, and support pole once and multiple reciprocating

processing technology, can greatly improve the efficiency of woodworking lathe and milling

machining processing

6.DXF importing processing function, simplify generation process of processing document

7.Adopt laser shape scanning directly generate processing code, greatly reduce the operating

requirements of the workers

8.USB communication function, support U disk process file copy and upgrade system, easy

maintenance

9.System diagnostics function make customers can self-diagnose some of the hardware

10.Wireless remote control